Control Panel (Part 1)

STEP 7: Install switches

Three types of industrial switches are used on the control panel: Pushbutton switches, selector switches, and key selector switches.

Three types of industrial switches are used on the control panel: Pushbutton switches, selector switches, and key selector switches.

The protection rating of the switches we use is unknown but is likely IP65 or IP54 at the very least, both of which are more than adequate for our brewery usage.

Industrial switches are different from most other switches so some explanation is in order.

The exposed part of the switch that the user pushes or turns is called the 'operator' or 'selector'. Operators can be 'maintained' or 'momentary'. A 'momentary' operator will spring back when it is let go while a 'maintained' operator will stay in position. All of the selector and key selector switches in our control panel have 'maintained' operators while the single pushbutton switch we use has a 'momentary' operator.

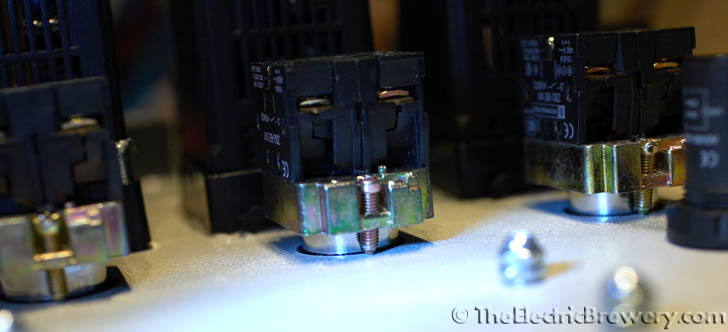

When the operator is actioned, it activates the contact block(s) on the inside of the control panel. Contact blocks are simple on/off switches that come in either 'normally open' (NO) or 'normally closed' (NC) varieties. There's typically room for two contact blocks to be screwed directly to the body and additional contact blocks can be piggybacked off those two in any combination as required.

While most of our switches and pushbuttons came with both a NO and NC contact block, we almost exclusively use the NO in our setup. The exception is the 3-way switch labelled 'ELEMENT SELECT' used to switch between heating in the Boil Kettle and Hot Liquor Tank, it uses two NO contact blocks.

Pushbutton, selector, and key selector switches:

To mount the switches, loosen the two mounting screws and then turn the operator a quarter turn to pull it free from the metal body. Some switches (most notably pushbuttons like the one above) may have a little L-shaped tab you have to pull out slightly first. Do not force the switches apart. They all come apart easily.

Once the operator and body are separated, place the operator through the hole in the door (making sure that the rubber gasket is on the outside of the door), click and turn it in the metal body, and then tighten the mounting screws with a screwdriver until the assembly is held tightly against the door. Even though the body on some models may be metal, do not overtighten or you may crack it . If the body does not shift or turn when the operator is actioned, it's tight enough.

We tried a few different types of switches before settling on these ones with metal bodies. Some of the all plastic ones we tried simply did not seem like they would last - even the contact blocks used really cheap parts and did not always switch properly.

Close-ups of switches mounted on the door: