Wort Chiller

STEP 1: Attach the 'wort in' quick disconnect

If you are using the recommended convoluted counterflow chiller skip the first part of this step as 1/2" NPT female fittings are already attached. You will not need to add the compression fittings or o-rings. This modified version of the chiller did not exist when we built our original brewery.

We need some way to connect one of the standard male quick disconnects to the counterflow chiller so that we can attach the hoses we made. The problem now becomes, how do we connect a male quick disconnect with a 1/2" NPT male fitting to the bare 5/8" copper pipe found on the chiller?

Permanently soldering (sweating) on some sort of brass 1/2" NPT female fitting first would work, but in our solution we use a stainless steel compression fitting instead which doesn't require any soldering (for those that aren't comfortable using a propane torch and/or do not want to use brass in their setup).

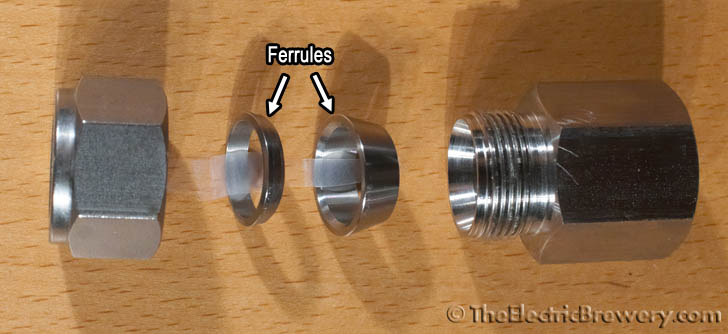

We can't use this stainless steel compression fitting directly on the copper pipe as it would simply crush the copper while it was tightened. The ferrules (which form the tight seal as they are compressed) are stainless steel which is considerably harder than copper.

We can't use this stainless steel compression fitting directly on the copper pipe as it would simply crush the copper while it was tightened. The ferrules (which form the tight seal as they are compressed) are stainless steel which is considerably harder than copper.

We have three options:

- Replace the ferrules with a softer nylon version (which will compress instead of the copper pipe).

- Use a rigid insert inside the copper pipe to avoid compressing it.

- Replace the larger compressing ferrule with a stack of 2-3 silicone high temperature o-rings.

We chose option #3 (o-rings) as we already had o-rings on hand that fit well: High temperature silicone o-rings (7/16" ID, 5/8" OD, 3/32" thick). These are the same o-rings used on Cornelius style beer keg quick disconnect posts, so we had a bag of 100 handy.

The inside of the stainless steel 5/8" compression to 1/2" NPT female fitting as received:

We replace the larger ferrule with three silicone high temperature o-rings. The smaller ferrule must be turned around to avoid cutting into the o-rings. When the two halves of the compression fitting are later screwed together the o-rings will slowly be compressed forming a tight seal between the copper pipe and the compression fitting.

Close-up of the ferrule and o-rings placed inside the compression fitting halves, showing the fit. The small ferrule has been turned around such that the flat end is facing upwards. This avoids cutting into the o-rings when the two halves are screwed together.

The following are placed on the bare end of the counterflow chiller copper pipe: The smaller end of the compression fitting, followed by the small ferrule (flat end facing up), and finally the three o-rings:

Wrap the threaded end of the male quick disconnect with PTFE white teflon thread sealant tape and use a wrench to attach it to the top half of the compression fitting. Then screw the two assembled parts to the bottom half of the compression fitting. Tighten until finger tight and then use a wrench to tighten another full rotation to compress the o-rings.