Hot Liquor Tank

STEP 4: Add the water input ball valve

As the water in the HLT is heated by the element it is recirculated by a pump to ensure that the temperature is consistent throughout the HLT. This movement also helps with heat transfer through the HERMS coil as the hot water will be flowing from the top of the kettle downwards, while the sweet wort in the coil will be flowing from the bottom of the coil upwards.

The water exits out the dip tube and ball valve at the bottom of the HLT. This dip tube and ball valve came with the kettle so there is no need to add them. What we need to add now is a water input ball valve to the top of the kettle.

In our setup the center of the water input ball valve is approximately 2" from the top of the kettle and approximately 4" from the handle.

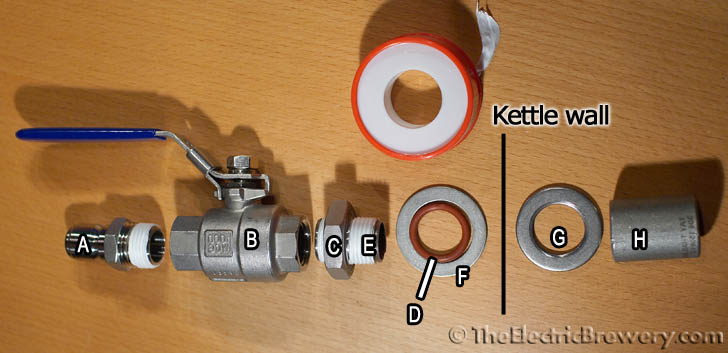

Water input quick disconnect with ball valve:

The parts outside the kettle for the water input are identical to what we used for the HERMS coil quick disconnects and ball valves:

The parts inside the kettle are different as we divert the water downwards at an angle so that it circulates around the HLT wall:

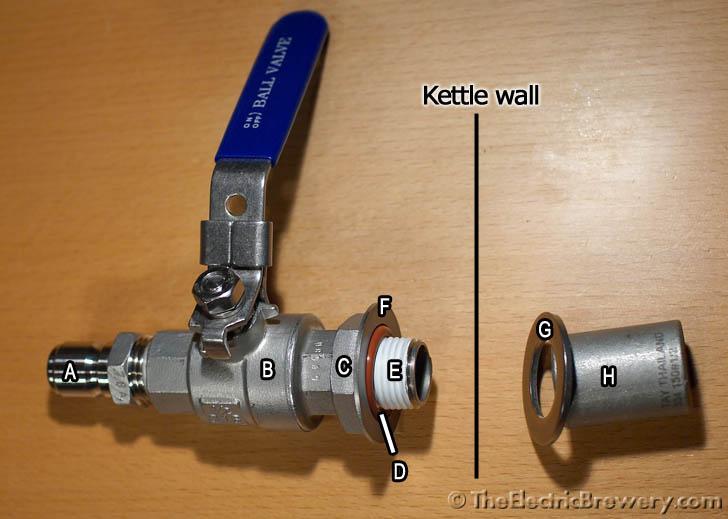

Like before, use a GreenLee 13/16" punch to create a 13/16" diameter hole for the ball valve. Wrap all threaded ends first with PTFE white teflon thread sealant tape to ensure a tight, leak-free fit. Then attach the ball valve and associated hardware to the inside/outside of the kettle as shown in the pictures below. Again, be careful to place the lock nut (part C) with the inner groove towards the kettle wall. The silicone o-ring (part D) will partially sit inside this groove to avoid being overly compressed between the lock nut and the kettle wall.

Breakdown of the water input ball valve connections:

(A) Stainless steel male quick disconnect 1/2" NPT male

(B) Stainless steel ball valve 1/2" full port

(C) Stainless steel 1/2" NPT lock nut

(D) Silicone high temperature o-ring (13/16" ID, 1-1/16" OD, 1/8" thick)

(E) Stainless steel nipple threaded 1/2" x close NPT

(F) Stainless steel washer/shim (1-1/8" ID, 1-5/8" OD, 0.062" thick)

(G) Stainless steel washer/shim (7/8" ID, 1-3/8" OD, 0.062" thick)

(H) Stainless steel full coupler 1/2" NPT female

(I) Stainless steel street elbow 1/2" NPT female x 1/2" NPT male

(J) Stainless steel 1/2" compression x 1/2" NPT male fitting

(K) 3" piece of 1/2" stainless steel tubing (from Step 1)

Tighten using a wrench until the whole assembly is firmly attached to the kettle wall. The short piece of stainless tubing should point down at approximately a 45 degree angle. This will cause the returning hot water to circulate around the kettle which helps with heat transfer through the HERMS coil. The parts you use to divert the hot water downwards are not critical. Feel free to substitute parts (I), (J), and (K) in the picture above with any other stainless parts you have handy.

The compression fitting side of part (J) should be tightened until finger tight and then a wrench should be used to turn it another full rotation to swage the ferrules inside onto the tubing, forming a tight seal.